แทงบอลออนไลน์ไม่ผ่านเอเย่นต์ ปรับปรุงขึ้นมาให้กับสมาชิกใช้งานกัน

แทงบอลออนไลน์ไม่ผ่านเอเย่นต์ในช่วงไม่กี่ปีที่ผ่านมา การเดิมพันกีฬาออนไลน์ได้รับความนิยมมากขึ้นในหมู่บุคคลที่ต้องการเพิ่มความตื่นเต้นให้กับเกมกีฬาที่พวกเขาชื่นชอบ ด้วยความสะดวกในการวางเดิมพันจากที่บ้านของตนเอง จึงไม่น่าแปลกใจที่หลายคนหันมาใช้แพลตฟอร์มการเดิมพันออนไลน์ อย่างไรก็ตาม อุปสรรคอย่างหนึ่งที่นักเดิมพันต้องพบเจอคือการต้องผ่านตัวแทนบุคคลที่สามหรือ “เอเย่นต์” เพื่อวางเดิมพัน สิ่งนี้ไม่เพียงเพิ่มขั้นตอนพิเศษให้กับกระบวนการเท่านั้น แต่ยังมักจะมากับค่าธรรมเนียมและความเสี่ยงเพิ่มเติมอีกด้วย นี่คือที่มาของแนวความคิด “ |บอลออนไลน์ไม่ผ่านเอเย่นต์” หรือการแทงบอลออนไลน์แบบไม่มีเอเย่นต์เข้ามามีบทบาท ในบทความนี้ เราจะเจาะลึกถึงคุณประโยชน์และข้อดีของการใช้แพลตฟอร์มออนไลน์ที่ช่วยลดความต้องในการมีผู้แทน มอบประสบการณ์ที่ดีขึ้นและคล่องตัวยิ่งขึ้นสำหรับนักเดิมพัน ด้วยการปรับแก้และอัปเดตอย่างต่อเนื่อง การพนันฟุตบอลออนไลน์ที่ไม่มีตัวแทนจึงกลายเป็นตัวเลือกที่สะดวกและเชื่อมั่นได้สำหรับแฟนกีฬาตัวยง มาดูกันว่าวิธีนี้มีการแก้ไขเพื่อประโยชน์ของผู้ใช้อย่างไร

เดิมพันออนไลน์โดยตรงโดยไม่มีตัวแทน

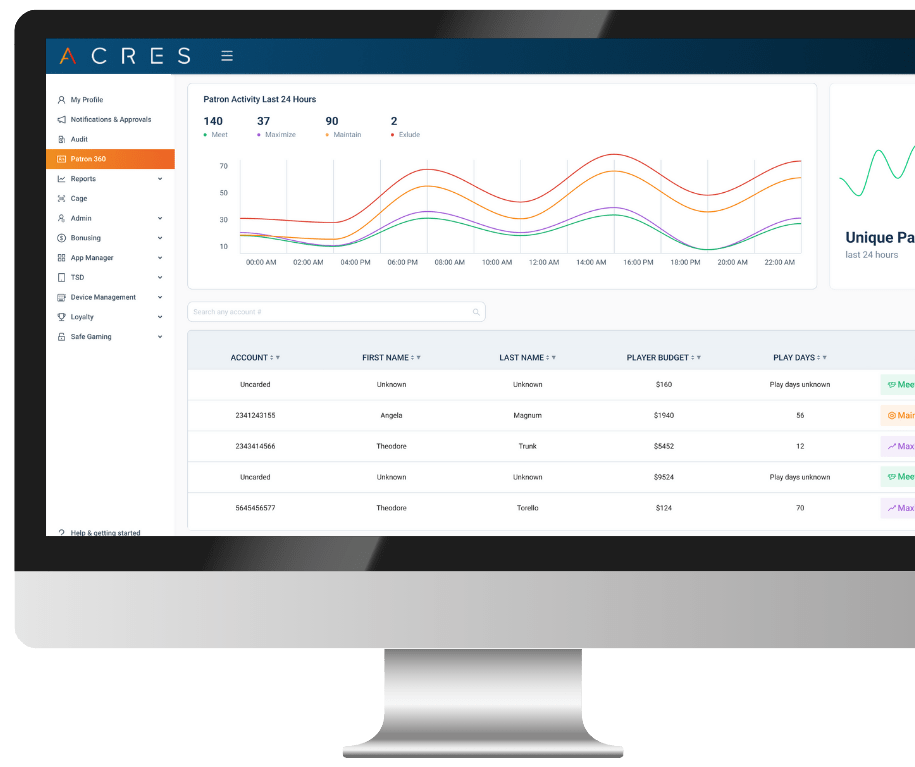

ในโลกของการเดิมพันออนไลน์ แนวความคิดของการเดิมพันออนไลน์โดยตรงโดยไม่มีตัวแทนหรือการเดิมพันออนไลน์โดยตรงโดยไม่มีคนกลางได้รับความสนใจอย่างมาก วิธีการนี้มีข้อดีหลายประการสำหรับผู้ใช้ ทำให้พวกเขาสามารถควบคุมการเดิมพันและการโต้ตอบได้โดยตรงโดยไม่จำเป็นต้องมีคนกลาง การกำจัดคนกลางจะทำให้ผู้ใช้สามารถสัมผัสกับการทำธุรกรรมที่เร็วทันใจขึ้น ความเป็นส่วนตัวที่ดีขึ้น และอาจมีโอกาสดีขึ้น ยิ่งกว่านั้น แพลตฟอร์มออนไลน์โดยไม่มีตัวแทนโดยตรงได้รับการปรับแต่งอย่างต่อเนื่องเพื่อให้อินเทอร์เฟซที่เป็นมิตรต่อผู้ใช้ มาตรการรักษาความปลอดภัยที่เชื่อถือได้ และตัวเลือกมากมายสำหรับผู้ที่ชื่นชอบการเดิมพันกีฬา สิ่งนี้ช่วยให้สมาชิกมีส่วนร่วมในกิจกรรมการเดิมพันได้อย่างมั่นใจ ในขณะที่เพลิดเพลินเจริญใจกับความสะดวกสบายและความยืดหยุ่นที่นำเสนอโดยแพลตฟอร์มเหล่านี้

แก้ไขประสบการณ์สำหรับสมาชิก

การแก้ไขประสบการณ์สำหรับสมาชิกในแทงบอลออนไลน์ไม่ผ่านเอเย่นต์เป็นสิ่งที่มีความสำคัญอย่างยิ่งเพื่อให้สมาชิกสามารถเพลิดเพลินกับการเดิมพันอย่างเต็มที่ได้เสมอ หนึ่งในวิธีการที่นำเสนอขึ้นมาเพื่อเพิ่มประสบการณ์ที่ดีกว่าคือการพัฒนาแพลตฟอร์มเพื่อให้มีอินเทอร์เฟซที่ใช้งานง่ายและนำเสนอข้อมูลอย่างถูกต้องและเชื่อใจได้ นอกเหนือจากนั้นยังมีการพัฒนาฟีเจอร์เสริมเพื่อเพิ่มความสะดวกสบายของสมาชิก เป็นต้นว่า ระบบชำระเงินที่เร็วและปลอดภัยมากเพิ่มขึ้น และเครื่องมือสนับสนุนต่างๆที่ช่วยทำให้สมาชิกสามารถกำหนดกฎเกณฑ์และควบคุมการเดิมพันของตนได้อย่างง่ายดาย

แทงบอลออนไลน์ไม่ผ่านเอเย่นต์ส่วนต่อประสานที่ใช้งานง่าย

เพื่อเพิ่มประสบการณ์ให้กับสมาชิกที่เข้าร่วมใน |บอลออนไลน์ไม่ผ่านเอเย่นต์ พวกเราได้ทำการแก้ไขแพลตฟอร์มอย่างมีนัยสำคัญ สิ่งสำคัญประการหนึ่งที่พวกเรามุ่งเน้นคือการพัฒนาอินเทอร์เฟซที่เป็นมิตรต่อผู้ใช้ซึ่งช่วยทำให้สมาชิกสามารถนำทางและเข้าถึงข้อมูลที่ถูกต้องและเชื่อใจได้ได้อย่างง่ายดาย นอกนั้นพวกเรายังได้นำเสนอคุณสมบัติเพิ่มเติมเพื่อเพิ่มความสะดวกสบาย ดังเช่นว่า ระบบการชำระเงินที่รวดเร็วและปลอดภัยเพิ่มขึ้น ยิ่งไปกว่านี้เรายังได้ใช้เครื่องมือต่างๆเพื่อช่วยสมาชิกในการสร้างแนวทางการเดิมพันของตนและรักษาการควบคุมการเดิมพันของพวกเขาได้อย่างง่ายดาย เป้าหมายของพวกเราคือการมอบประสบการณ์การเดิมพันที่ราบรื่นและสนุกสนานให้กับสมาชิกทุกคน

แพลตฟอร์มที่ปลอดภัยและไว้ใจได้

เราเข้าใจว่าความปลอดภัยและความวางใจเป็นสิ่งสำคัญที่สุดสำหรับสมาชิกที่เลือกใช้แพลตฟอร์มของพวกเราสำหรับการแทงบอลออนไลน์ไม่ผ่านเอเย่นต์ ด้วยเหตุนี้เราให้ความสำคัญกับการรักษาระบบรักษาความปลอดภัยที่เข้มงวด ทุกข้อมูลส่วนตัวและการทำธุรกรรมทางการเงินของสมาชิกจะถูกเข้ารหัสและรักษาความลับอย่างเข้มงวด ทางเรายังมีการตรวจสอบและควบคุมระบบอย่างเป็นประจำเพื่อให้มั่นใจว่าแพลตฟอร์มของพวกเราเป็นที่เชื่อมั่นได้ในเรื่องการป้องกันการฉ้อฉล ทั้งนี้เพื่อให้สมาชิกทุกคนสามารถเดิมพันและเพลิดเพลินเจริญใจกับการเล่นบอลออนไลน์ได้อย่างมั่นใจ

แทงบอลออนไลน์ไม่ผ่านเอเย่นต์ ขั้นตอนการฝากและถอนเงินที่ง่ายดาย

เพื่อให้สมาชิกทุกท่านสามารถเล่นแทงบอลออนไลน์โดยไม่ต้องผ่านเอเย่นต์และมีประสบการณ์ที่สะดวกสบายมากขึ้น เราได้ปรับปรุงแก้ไขระบบการฝากและถอนเงินให้ง่ายดายและสะดวกสบายที่สุด เพียงแค่ไม่กี่ขั้นตอนเท่านั้น สมาชิกสามารถทำการฝากเงินผ่านช่องทางออนไลน์ที่มีความปลอดภัยสูง ยกตัวอย่างเช่น การโอนเงินผ่านบัญชีธนาคาร หรือผ่านระบบอิเล็กทรอนิกส์ที่รวดเร็ว นอกนั้นสมาชิกยังสามารถทำการถอนเงินได้ในหลายวิธีตามความสะดวก พวกเรายังมีทีมงานรอดูแลและดำเนินการตรวจสอบการฝากถอนเงินอย่างรวดเร็วและปลอดภัย เพื่อให้สมาชิกทุกท่านได้รับประสบการณ์การเล่นแทงบอลออนไลน์ที่ไม่แค่เพียงง่ายดาย

โดยสรุป การเดิมพันกีฬาออนไลน์ได้รับความนิยมมากขึ้นในกลุ่มบุคคลที่ต้องการเพิ่มความตื่นเต้นให้กับเกมกีฬาที่พวกเขาชื่นชอบ ด้วยความสะดวกในการวางเดิมพันจากที่บ้านของตนเอง จึงไม่น่าประหลาดใจที่หลายคนหันมาใช้แพลตฟอร์มการเดิมพันออนไลน์ อย่างไรก็ตาม อุปสรรคอย่างหนึ่งที่นักเดิมพันต้องเผชิญคือการต้องผ่านตัวแทนบุคคลที่สามหรือ “เอเย่นต์” เพื่อวางเดิมพัน สิ่งนี้ไม่เพียงแค่เพิ่มขั้นตอนพิเศษให้กับกระบวนการเท่านั้น แต่ยังมักจะมาพร้อมกับค่าธรรมเนียมและความเสี่ยงเพิ่มเติมอีกด้วย นี่คือที่มาของแนวคิด “ |บอลออนไลน์ไม่ผ่านเอเย่นต์” หรือการแทงบอลออนไลน์แบบไม่มีเอเย่นต์เข้ามามีบทบาท ในบทความนี้ พวกเราจะเจาะลึกถึงคุณประโยชน์และข้อดีของการใช้แพลตฟอร์มออนไลน์ที่ช่วยลดความจำเป็นจะต้องในการมีตัวแทน มอบประสบการณ์ที่ดีขึ้นและคล่องตัวยิ่งขึ้นสำหรับนักเดิมพัน ด้วยการปรับแก้และอัปเดตอย่างต่อเนื่อง การพนันฟุตบอลออนไลน์ที่ไม่มีตัวแทนจึงกลายเป็นตัวเลือกที่สะดวกและวางใจได้สำหรับแฟนกีฬาตัวยง มาดูกันว่าวิธีนี้มีการปรับแต่งเพื่อประโยชน์ของผู้ใช้อย่างไร การเปิดตัวการพนันฟุตบอลออนไลน์โดยไม่ต้องผ่านผู้แทนทำให้ประสบการณ์การใช้งานของสมาชิกดีขึ้นอย่างมาก ไม่เพียงแต่ขจัดความต้องในการมีส่วนร่วมของบุคคลที่สามเท่านั้น แต่ยังช่วยให้กระบวนการเดิมพันราบรื่นและปลอดภัยยิ่งขึ้นอีกด้วย ด้วยการพัฒนานี้ พวกเราคาดหวังว่าจะได้มองเห็นจำนวนผู้ใช้ที่มากขึ้นและประสบการณ์การเดิมพันที่สนุกสนานและมีประสิทธิภาพมากขึ้นสำหรับทุกคน